Highfield’s state-of-the-art

26,000spm production facility is located in Weihai, China.

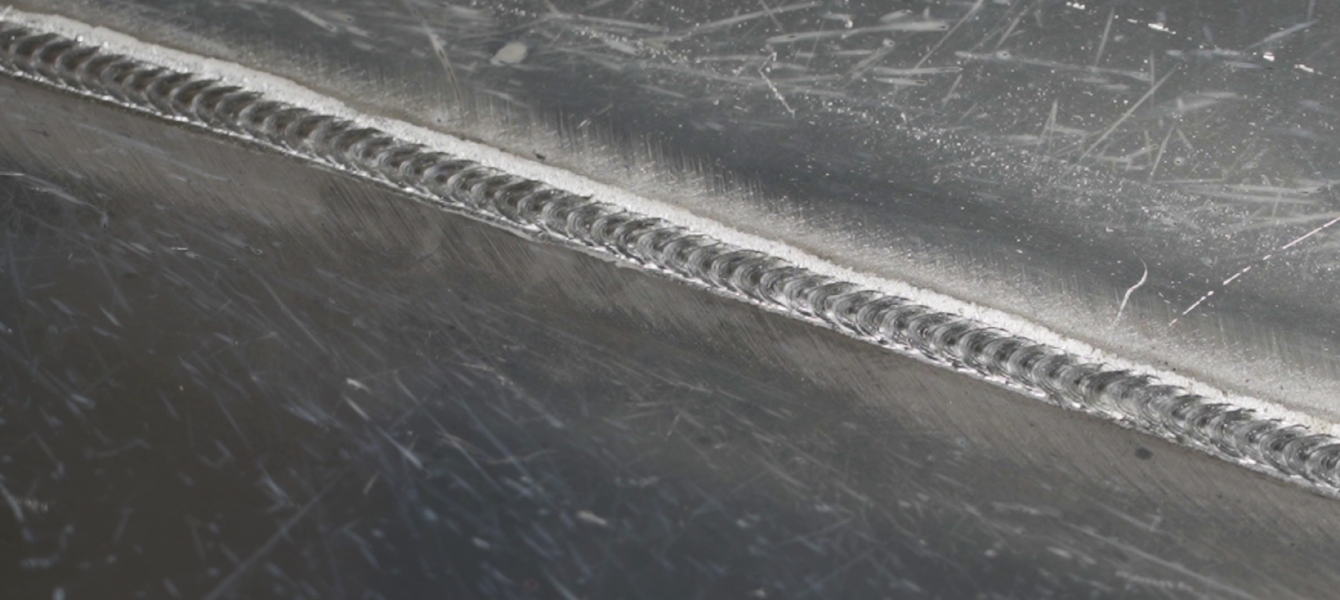

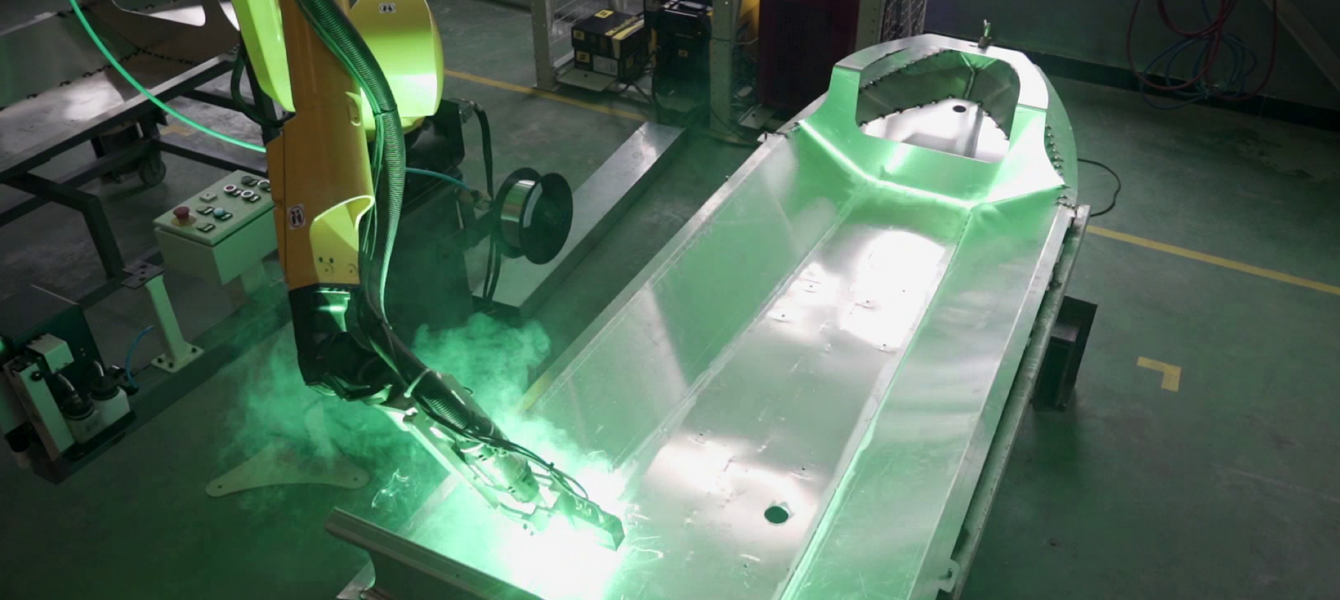

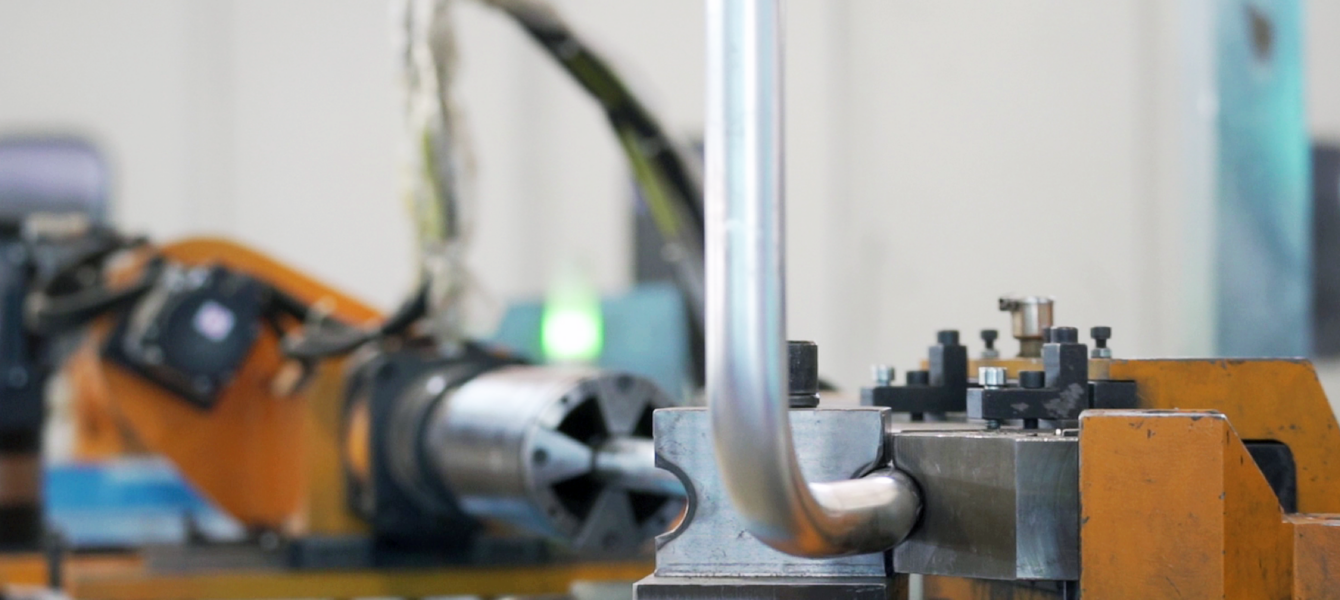

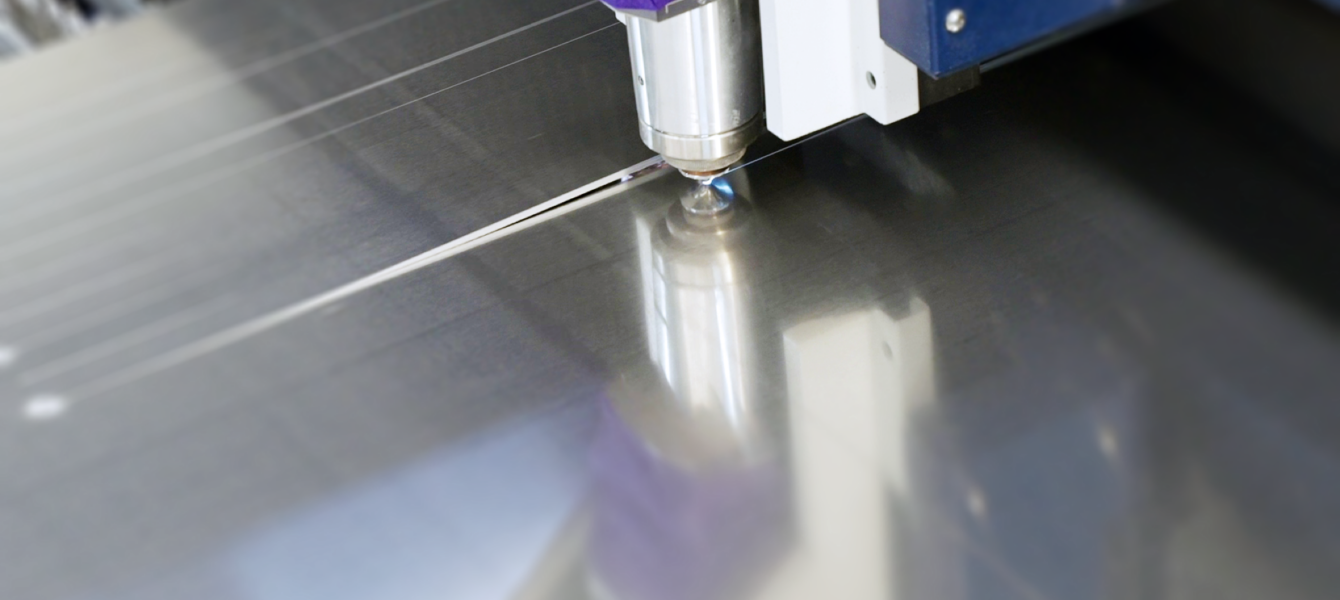

Highfield has pushed to remain at the forefront of cutting edge processes, using the highest technology available for each stage of production. From aluminium preparation to machine welding to powdercoating.

Factory Tour

Suppliers

-

Bravo – Scoprega

Bravo – Scoprega

Since 1964 Scoprega S.p.A. has been supplying the marine and camping markets, creating value for customers through high quality products.

-

Lalizas

Lalizas

LALIZAS manufactures and distributes over 10.000 products of marine accessories, safety equipment and miscellaneous items directly related to sea sports & activities.

-

Glenn Raven – Sunbrella

Glenn Raven – Sunbrella

Sunbrella is founded on the belief that fabrics should be both beautiful and functional. We began in the 1960s with the challenge of creating an awning canvas with a substantially longer lifespan than cotton. Sunbrella has become widely adopted for shade structures, marine canvas and upholstery fabric for both outdoor and indoor applications.

-

Glenn Raven – Sur Last

Glenn Raven – Sur Last

Sur Last® is a solution dyed polyester fabric designed to be flexible and easy for manufacturers to use. Its urethane coating enhances the stability of the weave and allows for greater water resistance, while also minimizing shrinkage and stretching. Sur Last features a high UV, water and mold and mildew resistance and has excellent tear and abrasion resistance.

-

Henkel

Henkel

Henkel’s LOCTITE is the trusted choice for engineered, high-performance adhesive, sealant and coating solutions. Designed to enable customer innovation, increase reliability and improve manufacturing operations, the LOCTITE expansive product portfolio offers solutions for the most demanding industry applications.

-

Spradling

Spradling

For over 50 years, Spradling International Inc. has offered design and performance solutions for nearly every application to enhance any seating environment. Spradling’s extensive library of marine quality coated fabrics has protected pleasure craft, commercial vessels and outdoor furniture for years through careful engineering and use of the finest raw materials to meet Mother Nature head-on.

-

Ultralon

Ultralon

Ultralon is now a leading supplier of high quality cross linked PE and EVA foams into the Sporting, Industrial, Marine and Orthotics markets. Originally based in Christchurch, New Zealand, the company now has manufacturing capability in Australia, New Zealand and Asia as well as a growing global network of sales outlets and distributors in the USA, Asia, APAC and Europe.

-

ORCA® – Pennel & Flipo

ORCA® – Pennel & Flipo

ORCA® fabrics offer high resistance to UV, abrasion, extreme temperatures…. They are designed for professional or leisure RIBs and inflatables. ORCA® range is available in more than 30 colors and 4 surface finishings.

-

Akzo Nobel

Akzo Nobel

AkzoNobel Interpon is the world leader in powder coatings. We offer effective coatings solutions for a wide range of applications, including furniture, automotive, IT, appliance, the architectural market and general industry.

-

Chinalco

Chinalco

Chinalco is the largest aluminum plates manufacturer in China. The company has over 40 years of history, it employs 8,000 people and produce 400,000 tons of aluminum per year. The 5052 and 5083 aluminum sheets produced by Chinalco are specifically manufactured for aluminum vessels used in salt water. These materials are DNV certified.

-

Mehler

Mehler

With more than 60 years of experience in the market of coated textile and over 600 employees over the world, Mehler is the market leader in the development and production of PVC coated fabrics. VALMEX® boat a high quality, PVC coated special fabric that deals best with the extreme physical stress– the perfect material for dinghies, banana boats, rafting boats, speed boats, RIBs and lifeboats.

ENVIRONMENT

When producing our boats, we use processes that are non-polluting and conserve energy and natural resources, making it economically sound and safe for employees, communities and consumers.

We make efforts to chose the right materials not only to build the Highfieldats tough and durable but also to make them environmentally friendly.

LIGHT WEIGHT

The Highfield aluminium hulls bring strength and light weight to the boats. As a consequence the boats require less horse power to propel them which means smaller outboard engine for same propulsion, lower fuel consumption and less CO2 emission.

ALUMINIUM

Aluminium recycling is the process by which scrap aluminium can be reused in products after its initial production. The process involves simply re-melting the metal, which is far less expensive and energy intensive than creating new aluminium. Recycling scrap aluminium requires only 5% of the energy used to make new aluminium. The nature of aluminium makes the material one of the few “infinitely recyclable” materials used in society; it can be recycled infinitely with no loss in quality.

POWDER COATING

It is a paint in powder form which is electrically charged as it is sprayed onto a surface to be coated and then baked in an oven, where the powder particles melt and fuse into a smooth coating. The result is a uniform, durable, high quality environmentally safe and attractive finish.

There are several advantages of powder coating over conventional liquid coatings:

- No volatile organic compounds

- No solvents, meaning reduced fire risk, reduced risk in application and disposal of waste

- Powder can easily be recycled as extraction systems gather excess powder

- Raw material research has produced powders that can be cured at lower temperatures meaning lower energy consumption

- Thermosetting powder coatings often have higher chemical / physical resistance – reducing cost and fuel consumption involved in transportation and storage.